Crane Resistoflex Hoses, pipes and accessories

Since 1999 Drotec distributes in Argentina the products Resistoflex, the leading supplier of highly corrosion-resistant engineering plastic-lined metal pipes to the chemical, petrochemical, pharmaceutical, and paper and paper industries in the United States and around the world. Resistoflex has been leading corrosive fluid handling technology for 40 years thanks to its quality, research and technical support. It has been ISO 9001 certified since 1995.

Resistoflex offers a complete range for the conduction of acids and bases, hydrocarbons, toxic, aggressive and any other fluid that wants to be carried safely.

Resistoflex manufactures a wide range of flexible PTFE hoses and products up to 4” for the most varied applications: truck unloading, gaseous chlorine, ultra-pure applications, high temperature, absolute vacuum, smooth and corrugated hoses. The terminals can be metallic, coated or flared flanges (only PTFE is in contact with the metal), or threaded, sanitary fittings, etc.

PTFE expansion joints

Resistoflex manufactures expansion joints up to 24” nominal diameter. 2, 3, 5 and 7 convolutions are offered to cover a wide range of length requirements and misalignment conditions. Its extraordinary performance, including its ability to work at high temperatures (232°C) and to resist absolute vacuum (depending on the diameter), is based on its careful manufacturing and the excellence of the raw material used.

The production method is extrusion molding, which does not require machining in order to ensure maximum use of the flexibility and mechanical strength of the PTFE resin used. The reinforcement rings are made of Nitronic 50, a super stainless steel alloy with chemical resistance similar to Monel. It has bolts to prevent excessive deformation and the material for them as well as for the flanges can be stainless or steel.

Resistoflex manufactures pipes and accessories up to 12" nominal diameter according to the norma ASTM F1545 on plastic-coated ferrous pipes, flanges and fittings. Compliance with this standard ensures that both ferrous and plastic materials, as well as the homologation and reception tests, ensure the quality of the manufactured products, as well as their performance.

Among other features, the products Resistoflex They stand out for their greater resistance to permeation and their ability to operate at high temperatures (up to 230°C) with absolute vacuum. The base material for the pipes is steel and stainless steel. Flanges can be made of steel, ductile iron or stainless steel.

The wide range of accessories, elbows, normal and instrument tees, reductions, crosses, visible passages, blind flanges, etc. allow to compose any industrial fluid conduction system. Material options for the plastic liner are PTFE, PVDF, or PP.

Resistoflex produces an attractive range of special products to complement the traditional line and also to offer safer alternatives for the most difficult applications.

Multiaxis: System of coated pipes in which the elbows and curves required are minimized by means of previously made bends.

Conquest: Coated pipe union system in which the traditional flanged unions are replaced by thermofused couplings that guarantee an absolutely watertight and safe installation.

Visible Passage: Coated accessory suitable for operation with absolute vacuum and high temperatures.

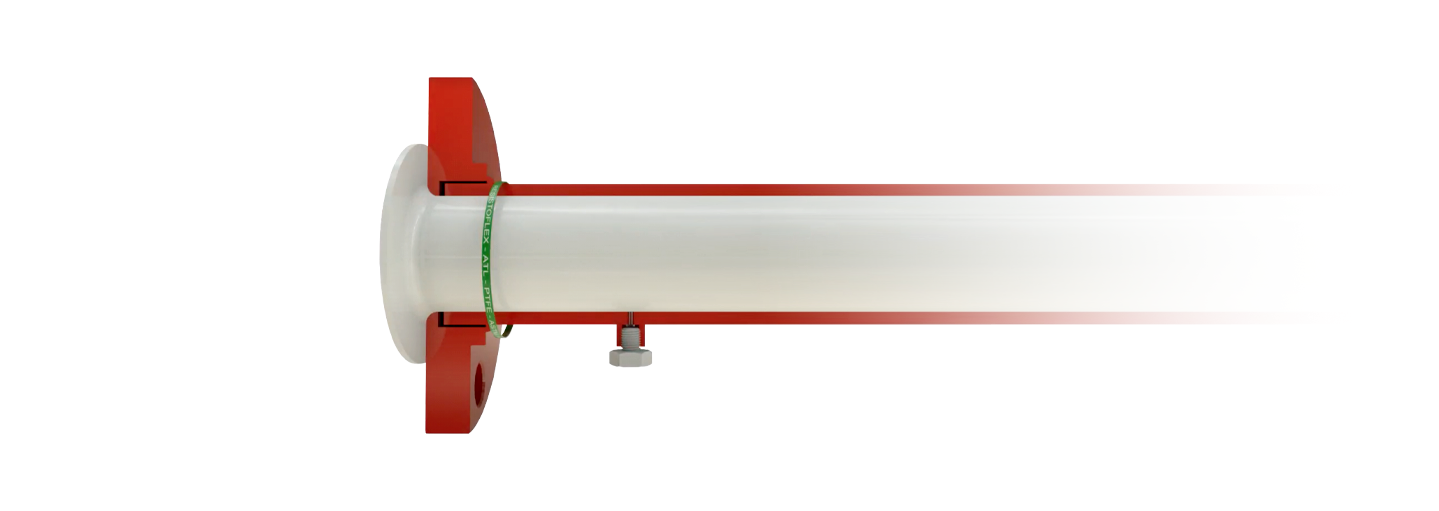

Dip pipe: Injector tube completely covered in PTFE with flange for attachment to the reactor.