Standardized centrifugal pumps Series NDQV

The NDQV series It is made up of 27 models of vertical centrifugal pumps. They are single-stage pumps with axial suction and radial discharge.

The main Applications of this series of centrifugal pumps are found in transfer and industrial processes: water, alcohols, vegetable oils, chemicals, dyes, biofuels, etc. and in general, any clean or slightly dirty liquid can be handled by this series of pumps. Recommended for corrosive liquids with the use of suitable materials and mechanical seals. Suitable for specific gravity greater than and less than 1.00 and viscosities greater than that of water. They reach flows of up to 400 m3/h and heights of up to 140m.

Vastly oversized bearings housed in robust make the NDQV series of centrifugal pumps suitable for heavy duty and continuous processes. All pumps have vent and drain connections.

Normally the pumps are delivered with a simple mechanical seal according to DIN 24960 with flow plan 1 for its lubrication. They can also be supplied with gaskets and double mechanical seals with thermosyphon, injection of liquid from an external source, flanges for stationary refrigerated or heated.

All 27 models of NDQ centrifugal Pumps, NDQ centrifugal Pumps, uses only 3 bearing support assemblies, shafts and casing to house the seal, providing great flexibility and interchangeability of spare parts.

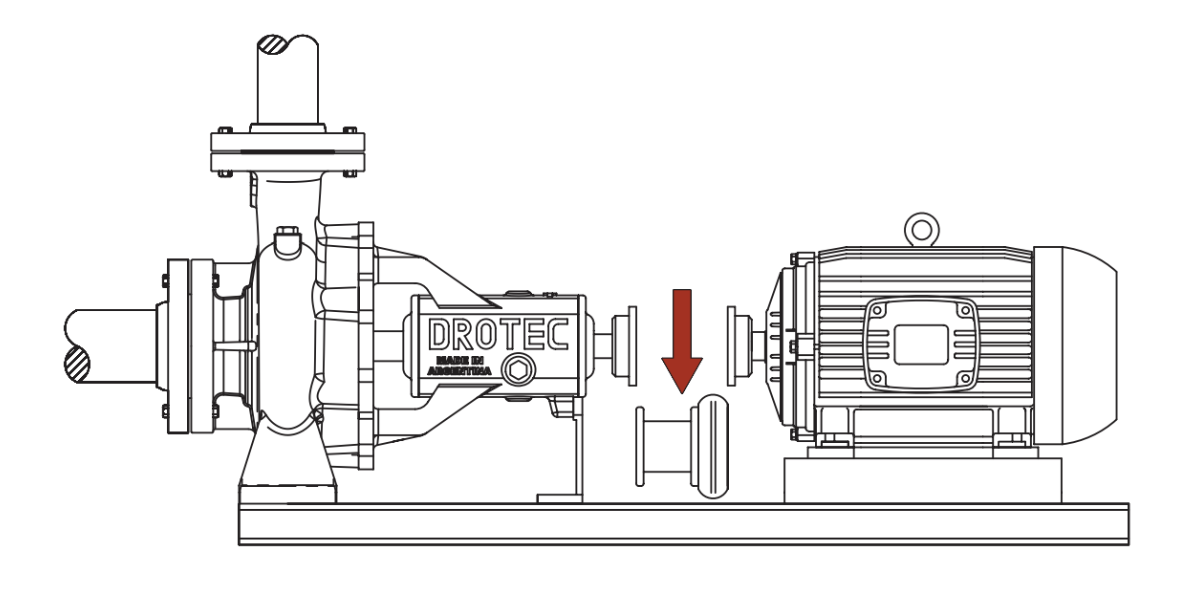

The design of these centrifugal pumps allows the rotating parts to be disassembled without dismantling suction or discharge piping using a spacer coupling. As shown in the figure, the pump body and electric motor must not be removed to disassemble the pump for inspection and repair. This allows you to preserve the initial alignment. Drotec supplies all NDQ series pump, base and motor assemblies with spacer couplings to take advantage of this advantage.

NDQV Cenntrifugal Pumps Construction materials: Gray or nodular cast iron, steels or stainless steels and special alloys.

An additional advantage s that the NDQV series of centrifugal pumps share the shaft and support assembly with the CAV series of centrifugal pumps. Thus, In the case of industries that need to handle clean liquids and those with suspended solids, they have centrifugal pumps that share spare parts in order to optimize maintenance management and reduce parts recommended in warehouses.