Unclogging Centrifugal Pumps CA series

The CA series is composed of industrial horizontal centrifugal pumps with axial suction and tangential discharge and cantilevered impeller that allow the passage of large suspended solids. The impeller of these centrifugal pumps can be either open or closed type, and also can be either swirl or vortex type. Largely oversized bearings housed in robust support are lubricated with grease in the standard version and with the oil lubrication with sight glass is optional. All CA series centrifugal pumps have vent and drain connections.

The main applications of these centrifugal pumps are liquids with solids in suspension, mud and slurries. They are suitable for continuous service and industrial processes. Recommended for corrosive liquids with the use of suitable materials. Suitable for specific gravity greater than and less than 1.00 and viscosities greater than that of water.

CA Series centrifugal pumps are normally supplied with hardened packings and wear sleeves although mechanical seals are available as options.

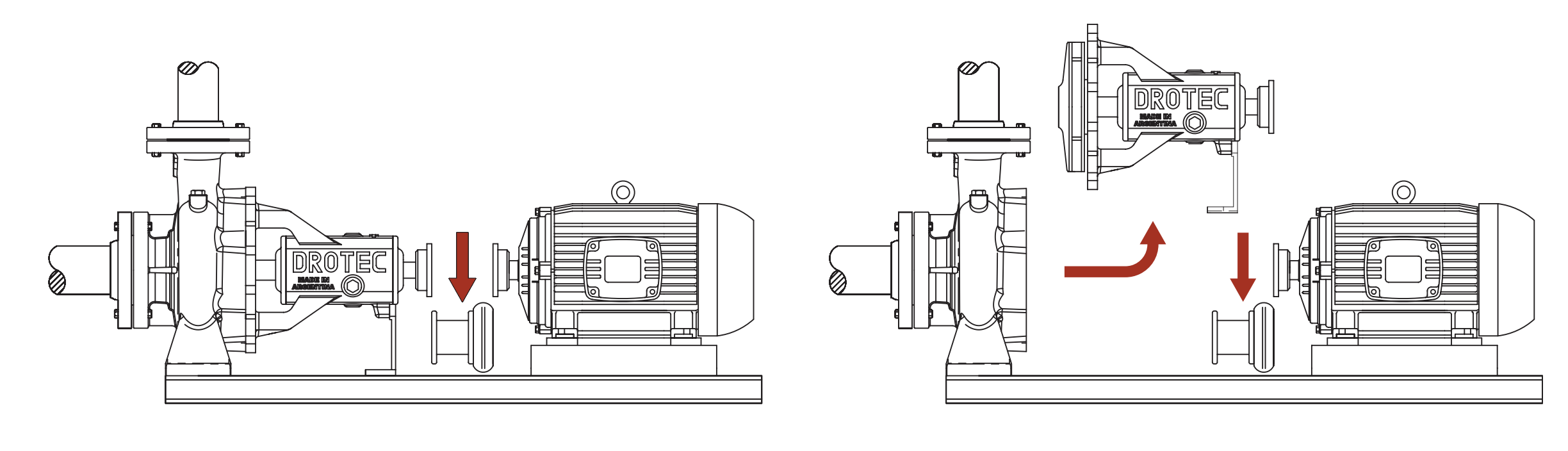

Its design allows disassembly of the rotating parts of the pump without disassembling suction or discharge pipes using a coupling with a spacer. As shown in the figure, the body of the centrifugal pump and the electric motor must not be removed to disassemble the pump for inspection and repair. This allows you to preserve the initial alignment. Drotec supplies all pump, base and motor assemblies of the CA centrifugal suspended solids pump series with spacer couplings to take advantge of this characteristic.

An additional advantage, is that the CA series centrifugal pumps share the shaft and support assembly with the NDQ centrifugal series.Thus, in the case industries that need to handle clean liquids and those with suspended solids, they have centrifugal pumps that share spare parts in order to optimize maintenance management and reduce recommended parts in warehouses.

The normal building materials They are cast iron and stainless steel. Other alloys are available.